EDDY CURRENT TESTING

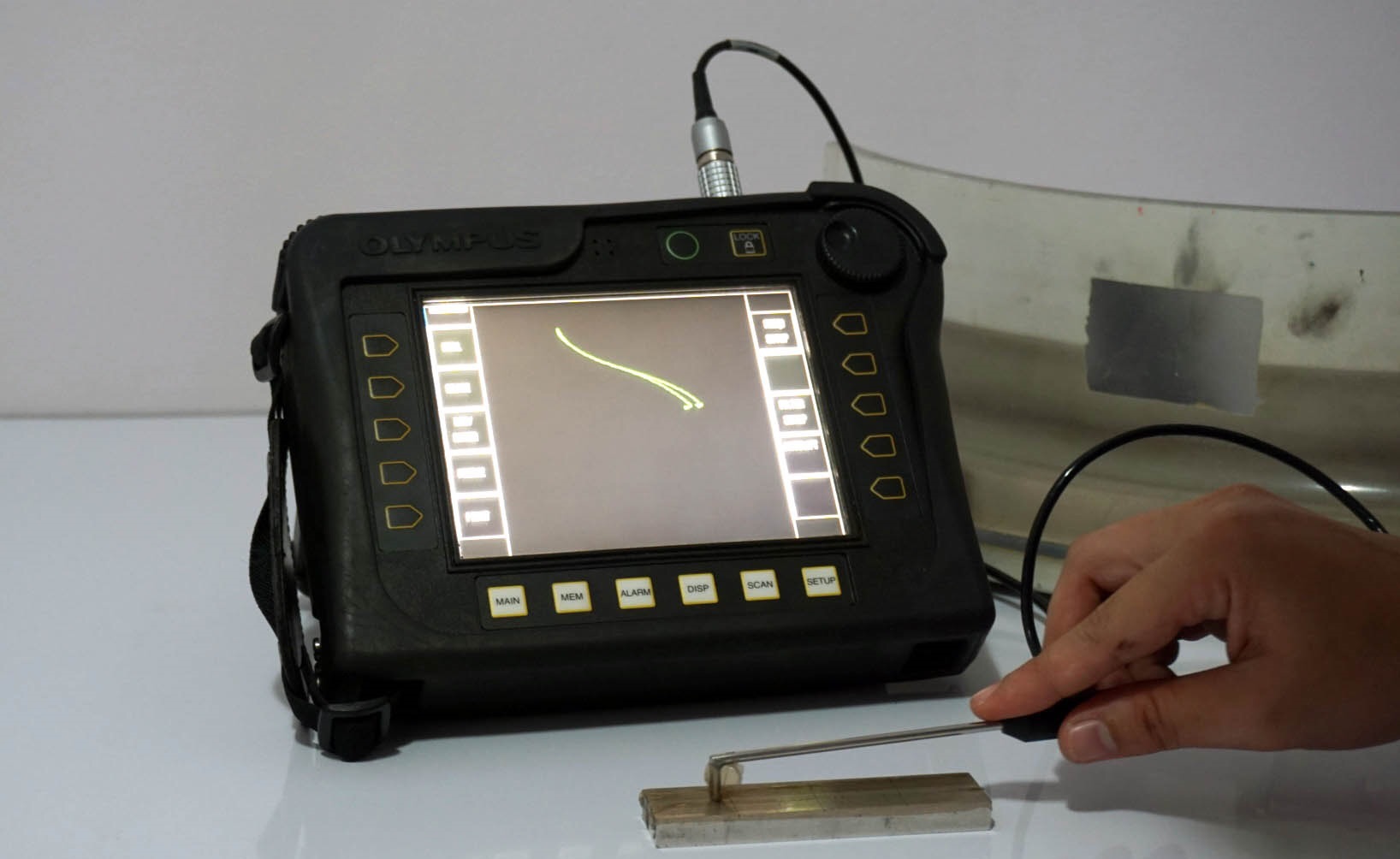

RWAN Engineering also conduct eddy current testing throughout the engineering and industrial sectors, using a variety of up-to-date procedures and techniques.

Eddy current techniques for nondestructive testing are based on the principles of electromagnetic induction. When a coil is excited by an alternation current and is placed near a conductive test object, the impedance of the coil changes. This change is associated with the fact that the primary field set up by the eddy current coil induces eddy currents within the electrically conductive object. For basic discontinuity detection, a discontinuity in the test object causes redistribution and reduction of the eddy currents within the test object and consequently changes the excitation coil impedance. The changes in the excitation coil impedance are used to infer information about the discontinuity.

RWAN Engineering offer a quick and cost effective service to the airline industry on a worldwide basis. We have approved engineers ready to inspect any kind of aircraft, whether it be routine or non-routine inspection requirements.

All our inspectors are level II or level III certified to EN4179/NAS410 or ASNT, where relevant.

Make an enquiry using our contact page or email for more information