Dye Penetrant

Penetrant testing is one of the oldest nondestructive test methods. The earliest use was on iron railroad wheels and was referred to as the oil and whiting process. Since those very early uses, penetrant testing has evolved into a very sensitive and useful process for detecting surface discontinuities. Penetrant is used in all aspects of aerospace products, such as raw castings, forgings, and weldments. The primary applications are after machining processes and in maintenance and overhaul facilities for detection of service induced cracking.

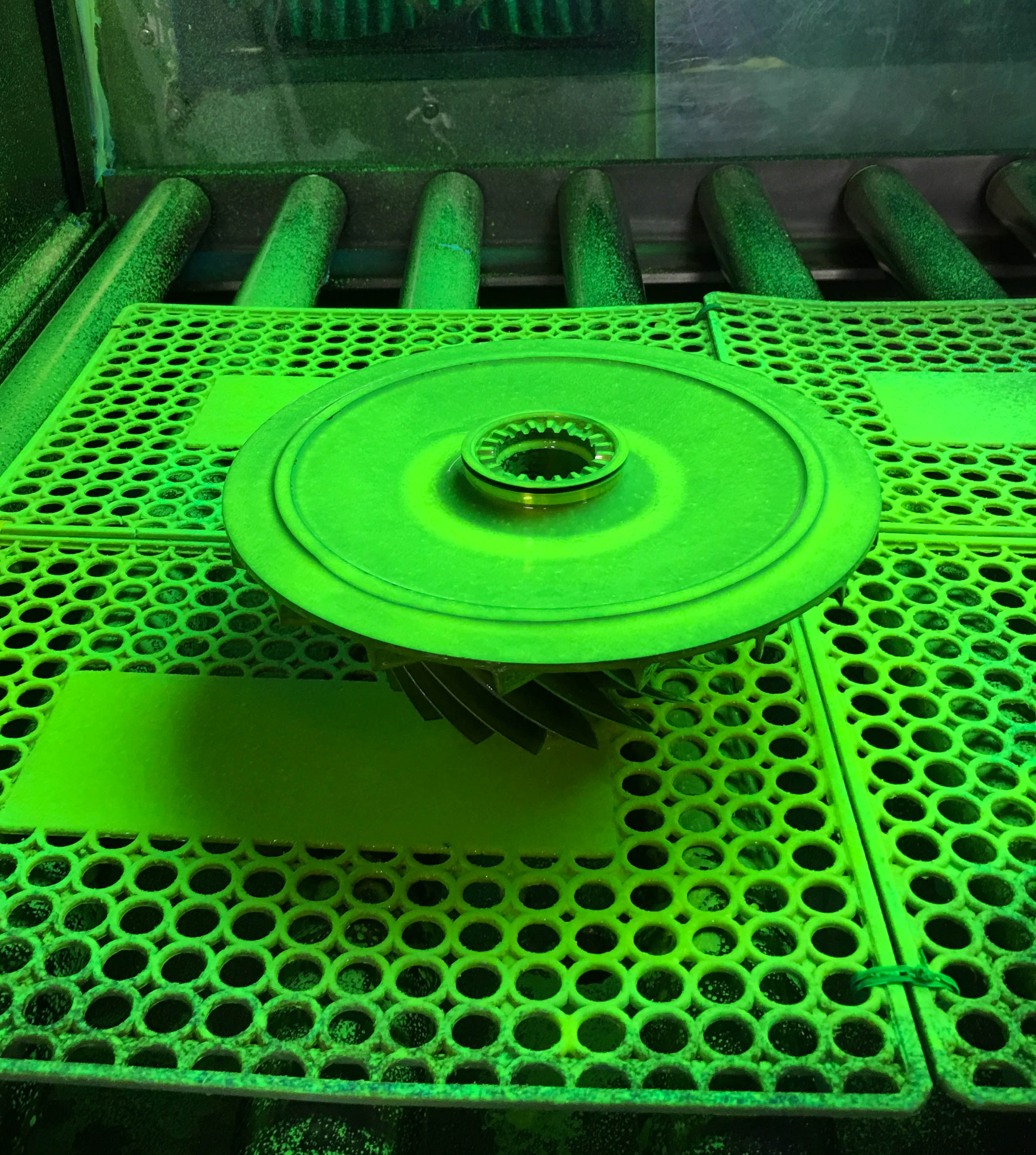

Two methods of penetrant testing are available: fluorescent and dye. Fluorescent penetrant and dye. Fluorescent penetrant testing is the required method of choice for most aerospace applications, in particular jet engine jet engine applications. Visible (dye) penetrant is less sensitive that fluorescent penetrant and therefore is prohibited on most aircraft applications but is often used on welds for space launch vehicles, spacecraft, and ground based equipment.

Make an enquiry using our contact page or email for more information